What are elastomers, and what types are there?

Elastomers are a type of very flexible polymer, which can be classified as thermosetting elastomers, which maintain their shape and state until the maximum temperature is reached and they disintegrate, and thermoplastic elastomers, which deform with exposure to heat and are moldable without losing properties.

What exactly are elastomers?

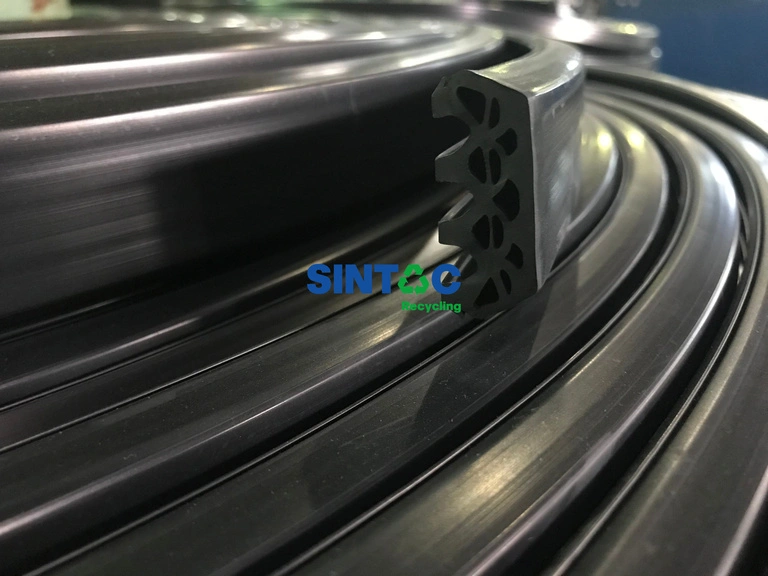

Elastomers, also known as TPEs, are characterized by being viscoelastic materials, which means that they are elastic polymers. They are made up of long molecules in the form of a long chain of carbon, oxygen, hydrogen or silicon, whose chemical structures have intermolecular cross-links. It is the perfect material to be used as an insulator since it has the ability to withstand torsion and deformation and can be moulded into different shapes. Elastomers are considered a specific type of polymer and include natural and artificial rubber.

The material is present in countless different industries such as automotive, electronics and sports, due to the fact that it provides a lot of properties that only this material can provide. They are very easy to form, especially when they are in their soft resin state. However, as they harden, they become resistant to temperature changes and other forms of material stress such as compression and stretching.

Elastomers are used in more industries for their durability. They easily withstand scratches, corrosion attacks from various chemicals, and the ravages of moisture and water immersion. And because elastomers do not conduct electrical current, they are excellent electronic insulators.

On a daily basis, we encounter elastomers in many everyday applications, including everything from tennis shoe soles to insulation covering telephone wires, to speaker wire covers.

The different types of elastomeric materials

There are many possible classifications of the various types of elastomers. The most widespread classification is according to chemical composition and the second classification is according to high-temperature properties.

- According to how they behave at elevated temperatures

- Thermosetting: They are those that maintain their state and shape at a given temperature increase, and when the temperature limit is exceeded, they degrade.

- Thermoplastics: They are those with a tendency to become moldable when subjected to temperature increases.

- According to their chemical composition

- Which refers to the multiple atoms contained in the main chains of this type of polymers.

- “O group“: when the chain contains oxygen atoms.

- “N group“: when the chain contains nitrogen atoms

- “M group“: when the chain contains methylene

- “R group“: when the chain contains rubber

- “Q group“: when the chain contains silicone rubber (MQ)

- “U group“: are polyurethane elastomers

- “T group“: for polysulfide rubber or “Thiokol”

- Which refers to the multiple atoms contained in the main chains of this type of polymers.

Applications of elastomers

Due to the multiple flexible, insoluble and elastic properties of elastomers, their applications are very diverse. It is worth mentioning the automotive industry such as tires, common consumer products such as neoprene suits or shoe soles, the construction industry as sealants to fill cracks, and medicine as molds, gloves, and prostheses, among many other applications.

At SINTAC we offer our customers our extensive catalog and our solid experience as a recycled plastic company.